The mining of metal ores is a cleaning-intensive process. Take, for example, the large, open-pit Cerro Verde mine near the Peruvian city of Arequipa. The copper mine produces around 270,000 tonnes of copper ore and 6,500 tonnes of molybdenum annually.

Read in:

Deutsch

Deutsch

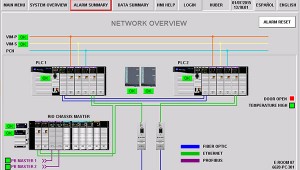

We configured the controls for the wastewater treatment plant and the ore-washing plant and designed them according to US regulations UL 508 A and UL 698 A. The scope of delivery included three switch and control systems.

One of which was built double-walled in stainless steel to reduce heat input under subtropical climate conditions.

Two Allen-Bradley ControlLogics control systems which are connected redundantly were used.

The system controls five filter step screens, two conveyor screws and two wash presses for the wastewater treatment.

The tight safety measures in mining have shaped the whole nine-month project. Just for on-site commissioning activities, a three-day safety check had to be completed in advance by our employees.