Digital twin

Deutsch

SPANGLER – the Plus of Digital Visions.

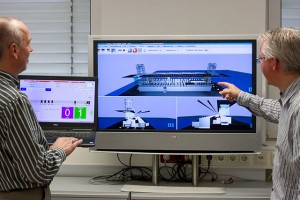

Programming a “digital twin” for a plant in order to simulate the processes of a plant under real conditions will be standard in automation technology in the next few years. There are several advantages. Complex correlations regarding control and material flow can be tested in real time and under realistic conditions. In this way the planning and engineering reliability is increased. Furthermore, the costs and the time for start-ups are significantly reduced.

Virtual start-up at SPANGLER

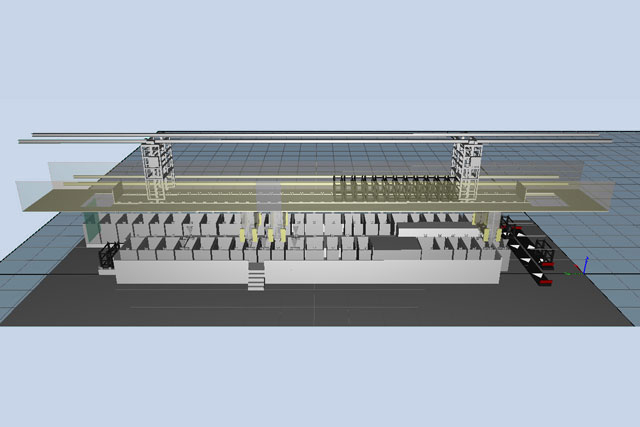

SPANGLER Automation concluded the conversion of an existing manufacturing plant of an automotive supplier. The plant which exists of three lines was converted to a new control technology and linked with the ERP system. This was carried out without shutting down the whole plant and with a minimum time of standstill. A retrofit with possible interruptions of production would not have been acceptable for the well-known supplier. Taking this into consideration SPANGLER offered a line-by-line conversion, planned and simulated in advance by a “virtual start-up”.

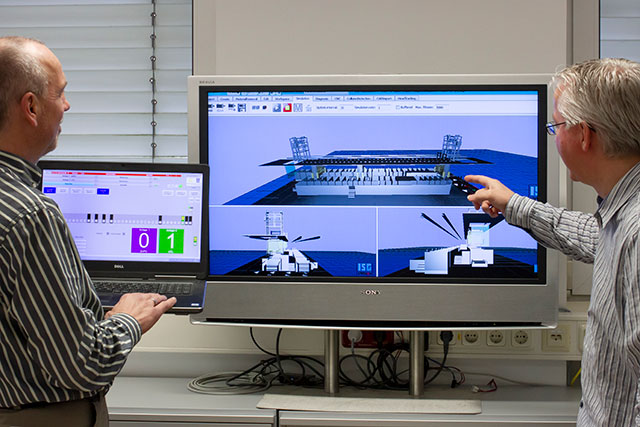

For the implementation the process automation team of SPANGLER designed a detailed “digital twin”. The simulations were connected to a failsafe Siemens PLC in order to thoroughly test the process procedures in real time and to adapt to the manufacturing conditions. The training of the operators could be done already in advance. The new control system which is 33 meters long and has 29 fields was assembled on-site and took over the control without any interruptions thanks to the prior virtual start-up.

Advantages for supplier and customer

SPANGLER Automation assesses the digital twin to be of high potential, not only due to reduced start-up times. Thomas Zenk, Manager Process Automation, explains: “The reduction of effort, either with new plants or with retrofit projects, is a significant advantage in competition for us and our customers.” Due to the positive experience SPANGLER will also focus on the digital twin in future.

Digital twin

Digital twin