Rockwell in Sevilla

Deutsch

SPANGLER – the Plus of Flexibility.

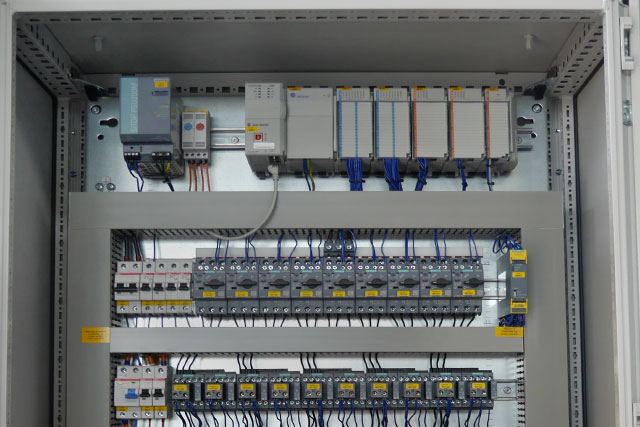

For the HUBER Technology España S.L.U. the control for thirteen multi-rake screens and two conveyor belts for a wastewater treatment plant near the Spanish city Sevilla were modernised. SPANGLER is always open to the customers’ wishes and can rely on comprehensive experiences of realised projects. Without great challenges an Allen Bradley control from Rockwell was therefore implemented in order to design the control technology in a sustainable and modern way. SPANGLER has already realised the entire range of Allen Bradley, from the MicroLogix to the redundant ControlLogix. In this case, the company chose the middle one, the CompactLogix.

Customer-specific solutions

Every plant is specially designed, programmed and manufactured for the intended field of application. Nevertheless, for plants which are only changed in details it can be fallen back on a standard range of programme and function blocks. Furthermore, SPANGLER can integrate every component that is technically possible. The reasons for these customer wishes are of any kind such as certification and approval reasons, personal preferences and the supply of replacement parts in a country or the integration in existing systems.

Free design in every component

Regarding the plant in Spain, its PLC was carried out with a CompactLogix and the PanelView Plus 7 HMI made by Allen Bradley. The SPANGLER solution was integrated in an already existing control system. Although this system allows the manual control of the drives for test purposes, it is, however, not authorised to control the automatic process from the control system. Thereby, SPANGLER can use the strengths of a control system such as the data archiving, the fault processing and the remote maintenance, without simultaneously neglecting the capabilities of a new plant or implementing a complete reconstruction of the control system architecture.