SPANGLER – the Plus of Precision.

No matter if burrs on motor and housing parts or residues of lubricants and coolants – in motor manufacturing precision and cleanliness are the most important things.

more ...

SPANGLER – the Plus of Know-how.

An extraction plant for recovery of essential oils, aromas or other natural extracts is based on longterm well-proven processes.

more ...

SPANGLER – the Plus of Innovation.

What is more obvious than to apply a kind of energy storage for electric power generated by renewable energy, which brings the power at any time to other sectors like traffic and industry in order to decarbonise them.

more ...

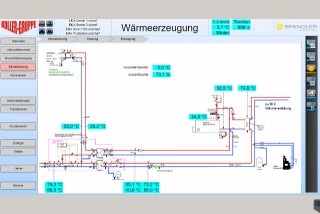

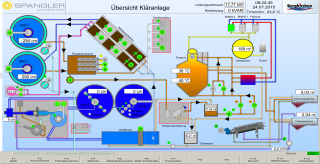

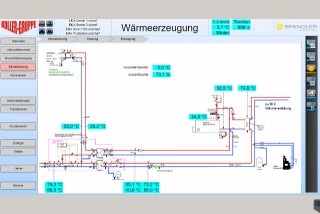

SPANGLER – the Plus of Communication.

They are the electronic supervisors of machine controls, data flows and data security: the Supervisory Control and Data Acquisition Systems (SCADA).

more ...

SPANGLER – the Plus of Food Technology.

Each potato differs in size, quality and dirt. For an automated processing the focus lies on intelligent manufacturing steps and the adherence to hygiene regulations.

more ...

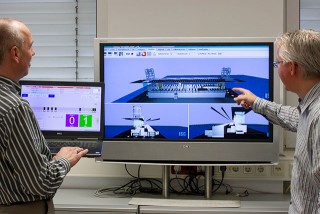

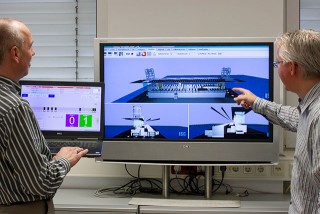

SPANGLER – the Plus of Digital Visions.

Programming a “digital twin” for a plant in order to simulate the processes of a plant under real conditions will be standard in automation technology in the next few years.

more ...

SPANGLER – the Plus of Failure Safety.

The Emirate Dubai doubles the capacities of its main waste water treatment plant in Jabel Ali. Based on a first stage of construction, the plant is expanded to a daily capacity of approximately 700,000 m³.

more ...

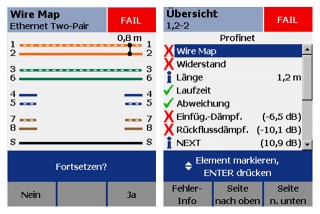

SPANGLER – the Plus of Industry 4.0.

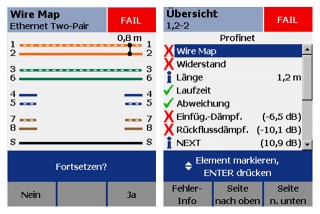

In automation technology besides serial fieldbuses Ethernet systems for the data communication are used to an increasing degree.

more ...

SPANGLER – the Plus of Vision.

SPANGLER GMBH appointed a new Managing Director on 01.01.2019. Christian Brandmüller changed from Sales Manager to the company’s management.

more ...

SPANGLER – the Plus of Safety.

As basic safety components brake systems require regular testing. The company Knorr Bremse AG is one of the leading international manufacturers of brake systems for rail and utility vehicles.

more ...

SPANGLER – the Plus of Speed.

Concrete buckets bring large amounts of concrete from the truck mixers to the installation site. The Florian Eichinger GmbH located in Mühlhausen manufactures installation site equipment under the keywords “Robust.Orange.Eichinger” which enjoys an excellent reputation not only in Germany but also around the world.

more ...

SPANGLER – the Plus of Renewable Energy.

The know-how of SPANGLER Automation has already been used in more than 30 production plants for biogas. The latest project was realised in Croatia.

more ...

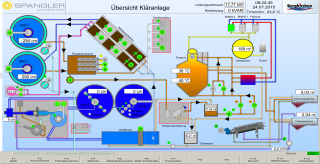

SPANGLER – the Plus of Data Consistency.

Innsbruck is a trendy winter sports centre, student city and Austria’s fifth largest populated area. There, SPANGLER has accompanied the extension of the municipal wastewater treatment plant, which energy-efficiently cleans the wastewater of the region and thus provides capacities for further population growth.

more ...

SPANGLER – the Plus of Recording.

Although wind power plants have gigantic dimensions, they are generally mass-produced products. The logistics of plant parts which are several meters large regularly becomes more difficult and time-consuming, e.g. to the Far East.

more ...

SPANGLER – the Plus of Building Installation.

Smart living – the trend of the reactive and networked building equipment for private households gets more and more interesting also for industrial solutions.

more ...

SPANGLER – the Plus of Flexibility.

For the HUBER Technology España S.L.U. the control for thirteen multi-rake screens and two conveyor belts for a wastewater treatment plant near the Spanish city Sevilla were modernised.

more ...

SPANGLER – the Plus of Security.

PM drives are motors whose rotor is equipped with permanent magnets. Due to their type of construction they promise users a higher degree of efficiency than the conventional asynchronous motors.

more ...

SPANGLER – the Plus of Perspective.

Glass is one of the most adaptable materials of today. There are innumerable fields of application from sheet glass to glasses and hotplate.

more ...

SPANGLER – the Plus of Data Processing.

The community Beilngries has always given attention to energy and cost efficiency since the construction of the municipal waste water treatment plant.

more ...

SPANGLER – the Plus of Technology.

A modern vehicle consists of several thousand parts; many of them, in particular in the interior, are made of plastic.

more ...

SPANGLER – the Plus of Internationality.

In the course of the extension of the waste water treatment plant Sulaibiya for HUBER SE, a worldwide operating company in the areas of water treatment, waste water treatment and sludge treatment, SPANGLER was assigned to carry out the control technology for the screen plant and the grit and grease trap.

more ...

SPANGLER – the Plus of Software Solutions

PLC programming is SPANGLER’s speciality but the company can also hold a lot of experience in the programming of individual software.

more ...

SPANGLER – the Plus of Flexibility.

Modernising a manufacturing process whilst the production is running is always a challenging task. SPANGLER Automation accomplished such a project for Knorr-Bremse AG, an internationally-active manufacturer of brake systems for rail and commercial vehicles.

more ...

SPANGLER – the Plus of Digitalisation.

Mühlhausen is a municipality in Upper Palatinate, about 15 kilometres south of Neumarkt. It comprises of 21 districts. SPANGLER has been commissioned to equip two sewage plants and a waterworks with modern and up-to-date control systems for this growing municipality, and to adapt the systems to the requirements of digitalisation.

more ...

SPANGLER – the Plus of Training.

It takes up to 22 hours for SPANGLER employees to travel to a customer, for example in South America. However, the journey of a customer to our company also takes a lot of time.

more ...

SPANGLER – the Plus of Future.

The main wastewater treatment plant in Vienna intends to cover its entire energy demand with self-produced sewage gas by the year 2020 as wastewater treatment plants belong to the biggest local energy consumers. Therefore, the operating company started the project E_OS

more ...

SPANGLER – the Plus of Communication.

Current developments and future challenges were the focus of this year’s SPANGLER Automation Day which was organised by SPANGLER together with suppliers and partner companies on 14 September. About 40 guests

more ...

SPANGLER – the Plus of Innovation.

The best ideas, the largest volumes of data, the most sophisticated structures are of little use if you cannot understand them or hardly find them again within the system. Therefore, SPANGLER Automation has used the system EPLAN for years to plan projects, to visualise designs and to arrange production and

more ...

SPANGLER – the Plus of Reliability.

A close cooperation with a strong partner is very important to be able to use the technological progress and the innovations in the automation and propulsion technology for the benefit of the customers. Since 2009 SPANGLER Automation has therefore been a certified member in the Siemens Solution Partner Program.

more ...

SPANGLER – the Plus of Quality.

The Jachenhausen Group is an administration union which supplies drinking water to around 15,000 residents in the administrative districts of Lower Bavaria, Upper Bavaria and Upper Palatinate. At the end of 2015, the association expanded their Ihrlerstein waterworks and equipped it with an activated carbon filter system

more ...

SPANGLER – the Plus of Topicality.

The health resort of Bodenmais is one of the leading tourism regions within the Bavarian Forest, and is located in direct proximity to the Bohemian Forest and the border to the Czech Republic. At the beginning of 2016, SPANGLER Automation installed and adapted the new process control system for the local sewage treatment plant.

more ...

SPANGLER – the Plus of Efficiency.

A modification of the sewage system was on the agenda in the Upper Palatinate district town of Neumarkt. Huber SE in Berching, an internationally active specialist for water and wastewater treatment, had installed a two-line screen plant for the pre-treatment of the wastewater, and SPANGLER Automation supplied the

more ...

SPANGLER – the Plus of Advancement.

In 1999/2000, the Verband (Association) Penzberg south of Lake Starnberg received a new sewage treatment plant. At the end of 2015, a renovation was due after 15 years of operation without problems. SPANGLER Automation updated the existing measurement technology and evaluation units to accord with state of the art technology.

more ...

SPANGLER – the Plus of Responsibility.

SPANGLER CEO Helmut Graspointner has been elected to the executive board of the Bavarian Umweltcluster [environmental cluster].

more ...

SPANGLER – the Plus of Safety.

Jordan is one of the most arid countries in the world. The once mighty river Jordan is now just a narrow creek. The demand for water is too large in the countries upstream. Steadily growing population figures and the climate change are stifling hopes of a rapid improvement in the situation.

more ...

SPANGLER – the Plus of the Future.

Renewable energy is the future. Burkhardt, a company based in the Upper Palatinate town of Mühlhausen, has been pushing the boundaries of what is technically possible for years now with its innovative products.

more ...

SPANGLER – the Plus of Development.

SPANGLER is currently booming, especially with regard to the area of renewable sun and wind energy. In this respect, a completely new development in Canada has just been installed.

more ...

SPANGLER – the Plus of Safety.

The mining of metal ores is a cleaning-intensive process. Take, for example, the large, open-pit Cerro Verde mine near the Peruvian city of Arequipa. The copper mine, first worked in the mid-19th century, is being modernised and expanded.

more ...

SPANGLER – the Plus of Accuracy.

The Central WWTP Chemnitz receives several deliveries of faecal matter from the surrounding villages every day. Fees must be paid according to the amount and composition of the faecal mass, paid by the waste management company per load.

more ...

SPANGLER – the Plus of Reliability.

The Neumarkt-based German company Burgis GmbH processes around 28,000 tonnes of potatoes a year for their potato specialities which are meanwhile nationally famous. Burgis relies in this respect on a high-quality, regional commodity from Bavaria.

more ...

SPANGLER – the Plus of Retrofitting.

Stainless-steel processing requires a clean surface. To achieve this, machined stainless steel is usually pickled in acid baths. All ferritic particles and the weld heat tinting are removed

more ...

SPANGLER – the Plus of Energy Management.

The conscious use of energy saves resources, reduces costs and creates a good image. The basis for this is making the energy flow visible and thereby ensuring that distribution and usage can be controlled.

more ...

SPANGLER – the Plus of Efficiency.

In Osterrönfeld, near Rendsburg in Schleswig-Holstein, directly on the Kiel Canal, the Max Bögl group has built a new production facility for concrete shells and concrete rings, from which System Max Bögl hybrid towers can be used to make wind turbines.

more ...

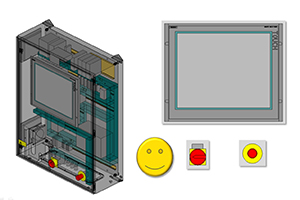

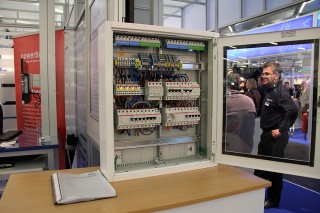

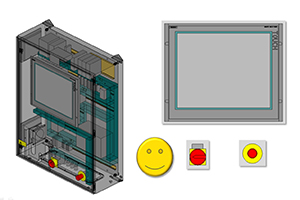

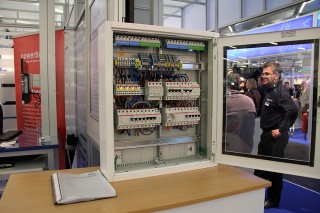

SPANGLER – the Plus of e-commerce.

Building distribution cabinets is a task reliant on the innate expertise of the electrician, but their everyday work often means that they don’t have time for this time-consuming job. Now SPANGLER Automation can also help in this case, as the company has acquired the licence for Easy Panel, a web-based software program for distribution-cabinet configuration.

more ...

SPANGLER – the Plus of Constancy.

Confidence is the basis for a successful long-term partnership. SPANGLER is interested in building such partnerships and therefore, the company clearly stands up for this aim in its mission statement “SPANGLER – the Plus of Partnership.”.

more ...

SPANGLER – the Plus of Innovation.

Being active is the key to good health. This old piece of popular wisdom is still true nowadays, and not only in terms of your health. Remaining active is also required for exploring new ideas and solutions.

more ...

SPANGLER – the Plus of Success.

Holding shares in the company, being actively involved in its success and at the same time being part of it. It was from this perspective that SPANGLER introduced profit-participation rights for its employees in 2011 –

more ...

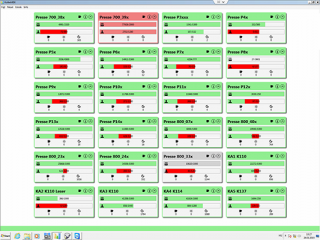

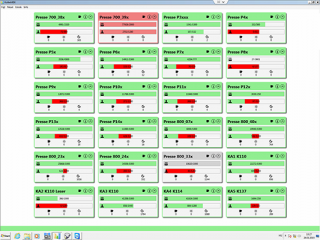

SPANGLER – the Plus of Customer Benefits.

SPANGLER Automation has developed a software system for the more efficient use of machine data for a supplier to the automotive industry. The company produces pressed parts for bodywork construction, in a plant in Hungary amongst other places. The aim was to balance out production figures which were in some cases widely divergent.

more ...

SPANGLER – the Plus of Sustainability.

In the past year, the city of Frankfurt has added a treatment plant for sewage sand to one of its waste water treatment plants in the Niederrad district. SPANGLER Automation designed and installed the switchgears for this, as well as the lighting and monitoring system. The new plant was put into operation at the end of 2014.

more ...

SPANGLER – the Plus of the Future.

In a record period of seven months (May to December 2014), SPANGLER achieved the automation of a new biogas plant in Dessau – from detailed engineering to SPS programming, control system creation, production, complete installation and finally commissioning. In addition to the planning and project development of twelve

more ...

SPANGLER – the Plus of Care.

Whether it is the wishes of the customers or the welfare of the employees – people are always at the focus for Hannelore Spangler. The Managing Director of SPANGLER Automation has received a lot of recognition for, on this basis, successfully positioning the family company on the international stage, constantly opening up new market opportunities,

more ...

SPANGLER – the Plus on the Internet.

Since the start of March, the website of SPANGLER Automation has had a new design and new contents. The most important are: under the heading “Projects”, the company presents reports from every sector whose solutions and processes

more ...

SPANGLER – the Plus of Hospitality.

7th May 2014, Messe München (Munich Trade Fair Centre), Hall Prinzregent, 18.00 hrs: The Bavarian reception with SPANGLER Automation is a fixed date within the scope of the biennial IFAT. A relaxed meeting without an official programme, and informal discussions along with live music and Bavarian delicacies.

more ...

SPANGLER – the Plus of Safety.

Work underground does not only mean mining. The drilling of underground pipes is no less strenuous than mining mineral resources; as with conventional tunnel drilling machines with so called “open shields” the machine operator sits directly in the drill head. Only there do they have a full overview, however they are exposed to high temperatures, dust or even flying particles from the degraded ground.

more ...

SPANGLER – the Plus of Hygiene.

The framework conditions of the foodstuffs industry are extremely demanding: the handling of foodstuffs requires absolute hygiene and precision, and the industrial mass production stipulates reliability and safety.

more ...

SPANGLER – the Plus of Continuity.

It was made official on 1st January 2014: Tina Lambert has been appointed to the Management of SPANGLER GMBH as of the beginning of the year. The daughter of Hannelore and Franz Spangler has been engaged in the family business for ten years now, and is responsible for the areas of Purchasing, Marketing and Public Relations, and subjects to do with strategic corporate development.

more ...

SPANGLER – the Plus of Reliability.

SPANGLER Automation has systematically prepared itself for the use of the new engineering platform by Siemens. Since 2009, the Dietfurt software specialists have systematically inspected the TIA (Totally Integrated Automation) portal in its application as a beta tester and orientated this to customer requirements.

more ...

Newsletter Archive

Newsletter Archive