Saving costs with IO-Link and remote access

Deutsch

SPANGLER – the Plus of Industry 4.0.

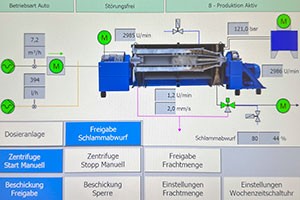

Our customer ISV Umwelt UG has equipped the sewage treatment plant Felsberg, a town in the North Hessian region of Schwalm-Eder, about 20 kilometers South of Kassel, with a new centrifuge for sludge dewatering. SPANGLER supplied the control and automation technology for this project.

The dewatering centrifuge

The centrifuge is fed with a mixture of thin sludge to be dewatered and flocculant previously prepared in a dosing station. Due to the high speed and the resulting centrifugal force in the centrifuge, the suspension is separated. Because of the higher density, the solid particles collect on the outer wall of the drum and the less dense liquid in the center of the centrifuge. The discharge screw inside the centrifuge drum rotates at a higher speed and thus conveys the settled particles to the solids discharge. The liquid drains off at the opposite side.

With Spangler towards Industry 4.0

For an optimum dewatering result a precise regulation of the quantity ratio between thin sludge and flocculant is necessary. The flow sensors and further sensors required for this are connected via the IO-link to the Siemens PLC (S7-1215C). The IO-Link devices can be centrally parameterized via the TIA portal and diagnostic information can be read out. In case IO-link devices are exchanged, the previous configuration is transferred automatically to the new sensor. Thus, standstill times can be minimized and the personnel expenses can be reduced.

For monitoring and display purposes, current machine data are transferred via a bus interface via S7 protocols to the on-site control system. The plant is operated via a touch panel TP1200 which is installed in the control cabinet front. For the remote access operation, the user interface via Sm@rt-Service can be transferred to an internet-enabled end device (e.g. laptop, mobile phone, tablet, …). A LTE modem enables access both from the specially created local W-LAN network and via VPN from the internet. The VPN-tunnel enables ISV Umwelt UG and Spangler to access the system remotely to offer for example service support or to install program updates. Furthermore, to save costs, the remote access was used to carry out the start-up.

Saving costs with IO-Link and remote access

Saving costs with IO-Link and remote access